Paper pulp packaging happens to be a Main concentrate for corporations throughout the world as they change clear of unsustainable elements toward eco-welcoming remedies. Molded pulp packaging provides a sustainable and price-productive way to supply significant-excellent packaging that may be customizable and biodegradable. 1 region driving innovation may be the introduction of substantial-performance pulp molding equipment, such as the Dwellpac Semi-Hotpress Machine. These machines assist firms streamline production while guaranteeing precision and trustworthiness.This article will take a look at The true secret options of high-efficiency pulp molding machines, maintenance tips for extended-expression use, methods to cut prices whilst maximizing output, And just how automation boosts generation and quality. no matter whether you're a company proprietor or simply a packaging Specialist, you may acquire precious insights to assist optimize your creation system.

Table of contents:

crucial functions of substantial-performance Pulp Molding Machines

routine maintenance techniques for very long-time period Machine functionality

Price tag-Saving approaches in output

How Automation enhances Output and excellent

critical attributes of higher-effectiveness Pulp Molding devices

High-effectiveness pulp molding machines are revolutionizing how molded pulp suppliers operate. The Dwellpac Semi-Hotpress equipment is a single these case in point. It stands out for its Highly developed Regulate process, substantial clamping accuracy, and seamless hydraulic efficiency. With functions like precision shaping and eco-helpful mould pressing technological know-how, it ensures that just about every eco-welcoming box packaging product or service is reliable in high-quality and toughness. This is vital for industries needing tailored methods like meals packaging, electronics, and industrial elements. these kinds of equipment also guidance A variety of custom molded pulp packaging wants, supplying considerable versatility in manufacturing.

routine maintenance tricks for very long-time period device general performance

sustaining a pulp molding machine is crucial to ensuring reliable output and maximizing its lifespan. normal upkeep duties consist of cleaning the molding surfaces, inspecting hydraulic methods for use and tear, and guaranteeing the Handle system is current for peak general performance. The Dwellpac device is built to simplify these procedures, allowing molded pulp suppliers to streamline maintenance. frequent inspections and proactive care not only lessen sudden breakdowns but will also enable retain the precision requirements necessary for significant-good quality paper pulp packaging.

Price tag-Saving tactics in Production

Cost-efficiency is a major problem for molded pulp brands. To save fees although maintaining high-quality, they're able to enhance content use by leveraging productive pulp mildew pressing engineering to attenuate waste, spend money on energy-efficient equipment just like the Dwellpac Semi-Hotpress Machine to cut back Strength consumption, and train personnel to fully benefit from State-of-the-art machines to stop faults that cause inconsistencies or wastage. Also, buying eco-helpful resources in bulk can help take full advantage of reduced rates and cut down Over-all manufacturing expenses. By adopting these procedures, brands can stay competitive while delivering large-high-quality, tailor made eco-helpful packaging to clientele.

How Automation increases Output and top quality

Automation happens to be a pivotal component of modern output processes. State-of-the-art pulp molding equipment manufacturers, for example Dwellpac, integrate automation to boost operational effectiveness. automatic devices, by which include functions like intuitive control panels and serious-time precision monitoring, reduce the chance of human glitches. This ensures that each mould made satisfies stringent high quality expectations. With automation, businesses could also take care of big-scale production operates much more successfully, meeting specific deadlines though generating molded fiber packaging at competitive rates. On top of that, the steady excellent realized through automation reinforces consumer belief in eco-friendly packaging answers.

High-efficiency pulp molding machines are enabling companies to fulfill rising demand from customers for sustainable packaging remedies. By investing in Sophisticated technologies, firms can generate tailored molded paper pulp products that eco friendly box packaging not just safeguard the setting but in addition present remarkable performance and durability. With progressive machines and thoughtful routine maintenance tactics, organizations can get over production difficulties, decrease operational prices, and present eco-friendly items that cater to world sustainability goals.

Shaun Weiss Then & Now!

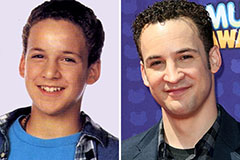

Shaun Weiss Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!